Our Success in Figures

Why Field Test?

Compostable packaging can play an important role in carrying food scraps into compost piles when included as part of a food scrap collection system.

Best Management Practices over time clearly suggest that going “all compostable” (not mixing recyclable and compostables, except for cans and bottles) within public collection areas create the best results for shipping clean materials to the receiving sites. See links below to case studies and waste audits commissioned by NatureWorks and performed by CMA.

Traditional practices for defining what is compostable have been to conduct ASTM D6400 and D6868 lab tests to show the materials used are safe in compost, will break down successfully into biomass and water (versus fragment), and will disintegrate adequately when processed in an industrial compost manufacturing system.

Since the ASTM standards were developed in the 1990s, composting process technologies have changed and evolved to accommodate feedstock changes with the addition of food scraps to yard waste collection both residentially and commercially. This is a benefit to the compost manufacturer as some technologies can now process materials in faster timeframes on the same land footprint. However, these differences can mean that products designed to break down in 90-180 day systems may not disintegrate adequately before being screened out, making the materials costly contaminants to the compost manufacturer that screens all inert and non-disintegrated packages and chunks that end up taking a long and expensive ride to the landfill, so everyone loses, especially the compost facility that must bear the cost for this directly.

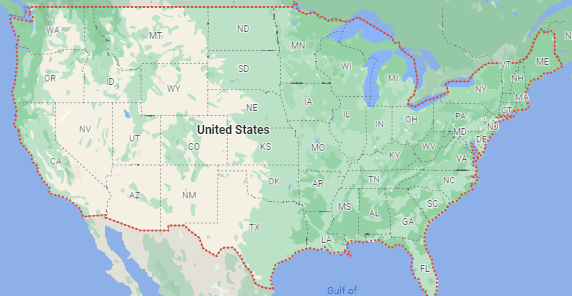

To address this, CMA is the only North American third=party certifier that has in-house technical specialist and chemists that review the ASTM lab reports to ensure compliance with ASTM D6400/D6868, as well as field specialists that conduct field disintegration testing in covered in-vessel (CMA-I), windrow processes (CMA-W) and aerated static pile systems (CMA-A).

This two step process ensures that the lab standards are met by the product designers, and that compost manufacturing facilities can reference the proper list for their site.